The

Walther Company

Historic Recollections

by

Ray Mackay

RECOLLECTIONS CONCERNING CARL WALTHER’S COMPANY AND ITS MECHANICAL CALCULATOR PRODUCTS |

| Carl Walther Company, of Germany came in to existence in circa 1886 and in 1903 began the production of fire arms for hunting and target practice. To put this in perspective for our American friends this was the year that France erected the Statue of Liberty in New York as a gift. In 1908 with a labour force of around fifteen Fritz Walther designed the first WALTHER automatic Pocket pistol. The fire arm products became renowned by sporting groups as the byword for precision and reliability. The great depression in 1923 saw a company under great stress for even a box of matches sold for 1 billion marks. In spite of difficulties the Walther Company managed to start again. |

By 1924 the

Company looking towards new products to assist its

recovery commenced making calculating machines based on

the pin drum mechanism. A method by which depending on a

selection lever a number of teeth remained protruding to

actuate a pinion located in a movable carriage. By 1924 the

Company looking towards new products to assist its

recovery commenced making calculating machines based on

the pin drum mechanism. A method by which depending on a

selection lever a number of teeth remained protruding to

actuate a pinion located in a movable carriage.  An electrified

version, the EMKD, was manufactured around 1929

and this model had independent carriage shift keys.

Similar mechanical machines were still available as late

as the early 1970’s and were designated the WSR

110 and WSR 160. One assumes the number

designated the capacity. An electrified

version, the EMKD, was manufactured around 1929

and this model had independent carriage shift keys.

Similar mechanical machines were still available as late

as the early 1970’s and were designated the WSR

110 and WSR 160. One assumes the number

designated the capacity. |

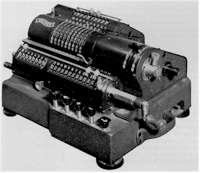

In 1931 the rather strange looking

machine on the left was added to the range. This machine

was designated the TASMA and worked as a print

out calculator. It appears to have sub total and grand

total keys as well as a clearance key. Each time an entry

was added to the keyboard the large crank was pulled

forward adding the information into the accumulators and

printing the keyboard data on to the paper roll. Prices

of such machines may be of interest to the readers

wishing to know them for historic purpose. The EMK

(Electric machine) with semi-automatic division was

around 850 Reichmark whereas the, EMKD model,

fully automatic division model sold for 950 Reichmark.

The least expensive Tasma listing machine sold

for 240 Reichmark and there were around seventeen models

in the range. Three models were electrically driven.

Little is reported about Walther during the years that

Europe was ravaged by war and one assumes, in the light

of how Governments work, that Walther, as a machine tool

company, would be forced to join the war effort in

manufacturing weapons. This is only an assumption on the

authors behalf, however, it is the likeliest scenario. In 1931 the rather strange looking

machine on the left was added to the range. This machine

was designated the TASMA and worked as a print

out calculator. It appears to have sub total and grand

total keys as well as a clearance key. Each time an entry

was added to the keyboard the large crank was pulled

forward adding the information into the accumulators and

printing the keyboard data on to the paper roll. Prices

of such machines may be of interest to the readers

wishing to know them for historic purpose. The EMK

(Electric machine) with semi-automatic division was

around 850 Reichmark whereas the, EMKD model,

fully automatic division model sold for 950 Reichmark.

The least expensive Tasma listing machine sold

for 240 Reichmark and there were around seventeen models

in the range. Three models were electrically driven.

Little is reported about Walther during the years that

Europe was ravaged by war and one assumes, in the light

of how Governments work, that Walther, as a machine tool

company, would be forced to join the war effort in

manufacturing weapons. This is only an assumption on the

authors behalf, however, it is the likeliest scenario. |

At the onset of

the war in 1939 the old factory, which Carl Walther

founded in Zella-Mahlis in the region of Thuringia

employed some 2000 people. By the end of the second world

war the factory was lost either because it was located in

the new state of East Germany or because it had been

bombed out of existence; information related to East

Germany is not easy to come by. Suffice to say a new home

was required. At first a team of Walther engineers worked

in makeshift workshops in the town of Heidenhelm. At the onset of

the war in 1939 the old factory, which Carl Walther

founded in Zella-Mahlis in the region of Thuringia

employed some 2000 people. By the end of the second world

war the factory was lost either because it was located in

the new state of East Germany or because it had been

bombed out of existence; information related to East

Germany is not easy to come by. Suffice to say a new home

was required. At first a team of Walther engineers worked

in makeshift workshops in the town of Heidenhelm. These workshops looked little better than

an army barracks platoon hut. Nevertheless, as a result

of their labours the Walther Company got ready to make

calculating machines again. New factories were built over

the next few years. First of all at Niederstotingen in

1948 manufacturing a new version of the RMKZ,

followed by factories at Königsbronn, Gerstetten, and

Ulm (1950). In a very short time the plants are in full

production and by 1947 were employing as many people as

the old plant was employing in 1939. In addition the

plants had the very latest in technology, new machine

tools, new presses and advanced techniques. It was not

very long before the Walther name was once again as

synonymous with quality equipment as it had been prior to

the war. New jobs created vacancies for new apprentices

and these were trained in the use of modern equipment

from an early age. Many hundreds of parts are required to

construct adding machines and these apprentices were

given the opportunity to learn from the ground up. These workshops looked little better than

an army barracks platoon hut. Nevertheless, as a result

of their labours the Walther Company got ready to make

calculating machines again. New factories were built over

the next few years. First of all at Niederstotingen in

1948 manufacturing a new version of the RMKZ,

followed by factories at Königsbronn, Gerstetten, and

Ulm (1950). In a very short time the plants are in full

production and by 1947 were employing as many people as

the old plant was employing in 1939. In addition the

plants had the very latest in technology, new machine

tools, new presses and advanced techniques. It was not

very long before the Walther name was once again as

synonymous with quality equipment as it had been prior to

the war. New jobs created vacancies for new apprentices

and these were trained in the use of modern equipment

from an early age. Many hundreds of parts are required to

construct adding machines and these apprentices were

given the opportunity to learn from the ground up. |

| Pride was engendered in the workforce and this was revealed in the design and quality of the machines. As the author was only involved with Walther Office equipment he has no knowledge of parallel projects although he believes the Ulm plant was dedicated to the manufacture of sporting guns. The fact such weapons were made is evidenced by the current Walther CP-88 CO2 Pistol (air pistol) which indicates the manufacture of such equipment continued. This does not interest us greatly and is merely added as a point of historic interest. Our interest is in the continuation of various mechanical calculating machines. Apart from newer versions of the old products the author knows of no new products until around 1952 when George Walther introduced a 220 cycle electronic adding machine ( the 101WS ? ) to the Hanover Fair. At this time the 220 cycles being the fastest machine available. The machine had a bulbous appearance in an, at the time considered fashionable, buff colour. The machine had an accumulator section that could be toggled to the front or rear of the machine to add or subtract as required. The numbers were entered through a ten or twelve digital keyboard, plus function keys (plus, minus, sub-total and grand total plus a reference key) in the case of Australian machines I seem to recall a ‘Whole Number Key’ that when down, jumped the pin box left to inhibit the racks normally used for 'sterling' operations. Numbers entered into the keyboard were stored in a pin box located under the keyboard and as each new digit was entered the pin box moved left one position until the complete number was entered. On pressing a function key the racks moved towards the rear of the machine until they were stopped by the pin box. At the same time the accumulator section toggled into the upper segment racks thus adding the corresponding number into the accumulator. Any carry overs dropped a secondary rack back one position and as the collector bail collected the mechanism to return it to normal the carries were added to the accumulator section. In printing to the paper the printing wheels were rotated into the position designated by the pin box and at the end of the operation the spring loaded wheel arms were released towards the platen putting an impression on the paper via a two colour ink ribbon. |

This

bulky machine was soon replaced by a rather neat version

called the Comptess (or S33). The new

‘Comptess’ was, in any case, a

delightful little piece of equipment in a two tone

plastic case and they were relatively inexpensive.

Excellent for the small business on limited funds. They

were a great selling item featuring a good sturdy

mechanism that performed almost flawlessly in the years I

worked on them. The S33 also had a sister

machine called the Multa 33 that multiplied

automatically. A heavy duty (sterling) machine called the

P12 was still available for those who liked good

solid machines. The possibility exists that the twelve in

the name indicated the least significant position on the

machine had a twelve tooth rack and twelve tooth pinions

for adding pence plus a ten shilling column (three rows).

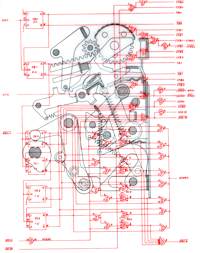

The cross section drawing illustrates the general

concept. I may at some later date fill in some specific

details of its operational concepts. This basic concept

however provided the basis for many models including a

model capable of multiplication (called the Multa 32 and

introduced around 1959). A model capable of duplex

operation and its counter part a multiplying duplex

machine the Multa GT. A model capable of

division called the DIWA 32. Some models had a

shuttle carriage that enabled them to be used as airline

ticket and railway ticket writers. This

bulky machine was soon replaced by a rather neat version

called the Comptess (or S33). The new

‘Comptess’ was, in any case, a

delightful little piece of equipment in a two tone

plastic case and they were relatively inexpensive.

Excellent for the small business on limited funds. They

were a great selling item featuring a good sturdy

mechanism that performed almost flawlessly in the years I

worked on them. The S33 also had a sister

machine called the Multa 33 that multiplied

automatically. A heavy duty (sterling) machine called the

P12 was still available for those who liked good

solid machines. The possibility exists that the twelve in

the name indicated the least significant position on the

machine had a twelve tooth rack and twelve tooth pinions

for adding pence plus a ten shilling column (three rows).

The cross section drawing illustrates the general

concept. I may at some later date fill in some specific

details of its operational concepts. This basic concept

however provided the basis for many models including a

model capable of multiplication (called the Multa 32 and

introduced around 1959). A model capable of duplex

operation and its counter part a multiplying duplex

machine the Multa GT. A model capable of

division called the DIWA 32. Some models had a

shuttle carriage that enabled them to be used as airline

ticket and railway ticket writers.

|

Others with duplex registers could be

programmed to work as small ledger machines producing

debit and credit dual column balance sheets. Others with duplex registers could be

programmed to work as small ledger machines producing

debit and credit dual column balance sheets. A rotating tabular rack with stop pins to locate the carriage was introduced and this allowed it to be rotated to one of four user selectable positions. As racks were available one assumes that many racks could be stocked for varying the operation to suit the job.

|

The machines took on a squarish form as per

the illustration to the right. The Walther Company was

obviously very aware of this `writing on the wall’

as rapid changes were made to cater for the new era. The

first signs were drawings that incorporated electronic

gates in order, one assumes, to create the image of a

very up to date company. Electronic models of the Walther

started to be produced however the state of the art had

ever changing goal posts. Everything was moving very

quickly, some may argue too quickly. The machines took on a squarish form as per

the illustration to the right. The Walther Company was

obviously very aware of this `writing on the wall’

as rapid changes were made to cater for the new era. The

first signs were drawings that incorporated electronic

gates in order, one assumes, to create the image of a

very up to date company. Electronic models of the Walther

started to be produced however the state of the art had

ever changing goal posts. Everything was moving very

quickly, some may argue too quickly. |

The author

continued on in the industry however track of the Walther

and the Company was lost around February of 1979. By that

time several electronic machines manufactured by Walther

were in full production but Companies like H.W. Egli (MADAS)

and Walther did not seem to fit in this new world. By the

mid eighties even electronic machines were being updated

almost as quickly as the schematics and drawings touched

the drawing board. The author

continued on in the industry however track of the Walther

and the Company was lost around February of 1979. By that

time several electronic machines manufactured by Walther

were in full production but Companies like H.W. Egli (MADAS)

and Walther did not seem to fit in this new world. By the

mid eighties even electronic machines were being updated

almost as quickly as the schematics and drawings touched

the drawing board.

|

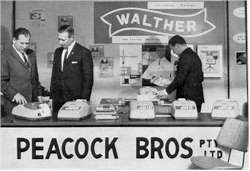

This report covers memories of only a small

area of a very large company. The recollections cover

only the mechanical calculator aspects of Walther.

Details and knowledge were gained from an association of

some twenty years as service manager of Peacock Bros of

Melbourne, Australia. The information is provided in

response to questions received via the Internet. Every

endeavour has been made to keep the recollections

accurate. The information is to be considered available

for educational purpose however, it may not be used for

profit or gain. Logos and business names are the

properties of the respective companies. This report covers memories of only a small

area of a very large company. The recollections cover

only the mechanical calculator aspects of Walther.

Details and knowledge were gained from an association of

some twenty years as service manager of Peacock Bros of

Melbourne, Australia. The information is provided in

response to questions received via the Internet. Every

endeavour has been made to keep the recollections

accurate. The information is to be considered available

for educational purpose however, it may not be used for

profit or gain. Logos and business names are the

properties of the respective companies. |

| Copyright © Ray Mackay. December 1997 All rights reserved |